What is fiber optic instrumentation?

Fiber optics are widely known for their role in telecommunications, especially for transmitting data at very high speed.

But in the maritime and aerospace sectors, their potential goes much further.

They can be transformed into highly accurate sensors capable of detecting temperature variations or structural deformations.

By embedding small reflective patterns (called Bragg gratings) into the fiber, it becomes a line of sensors that continuously monitors mechanical and thermal stresses.

Each Bragg grating acts as a partial mirror reflecting a specific wavelength. When mechanical or thermal stress affects the fiber, it slightly alters the structure of the grating, causing a measurable shift in the reflected wavelength.

These micro-variations are analyzed by an optical interrogator, which sends light pulses and measures the returned signals. The raw data are then processed through a data acquisition unit, turning them into actionable insights: deformation mapping, overheating alerts, or dynamic stress monitoring.

Fibers can be:

- Embedded in composite materials during fabrication, for in-depth monitoring;

- Bonded or surface-mounted on existing metal or composite parts, for retrofit or targeted instrumentation.

This measurement system, free of electromagnetic emissions, monitors critical components without interfering with their function, achieving precision down to a few microns per meter. Being immune to electromagnetic interference, fiber optics ensure reliable measurements even in highly disturbed EM environments.

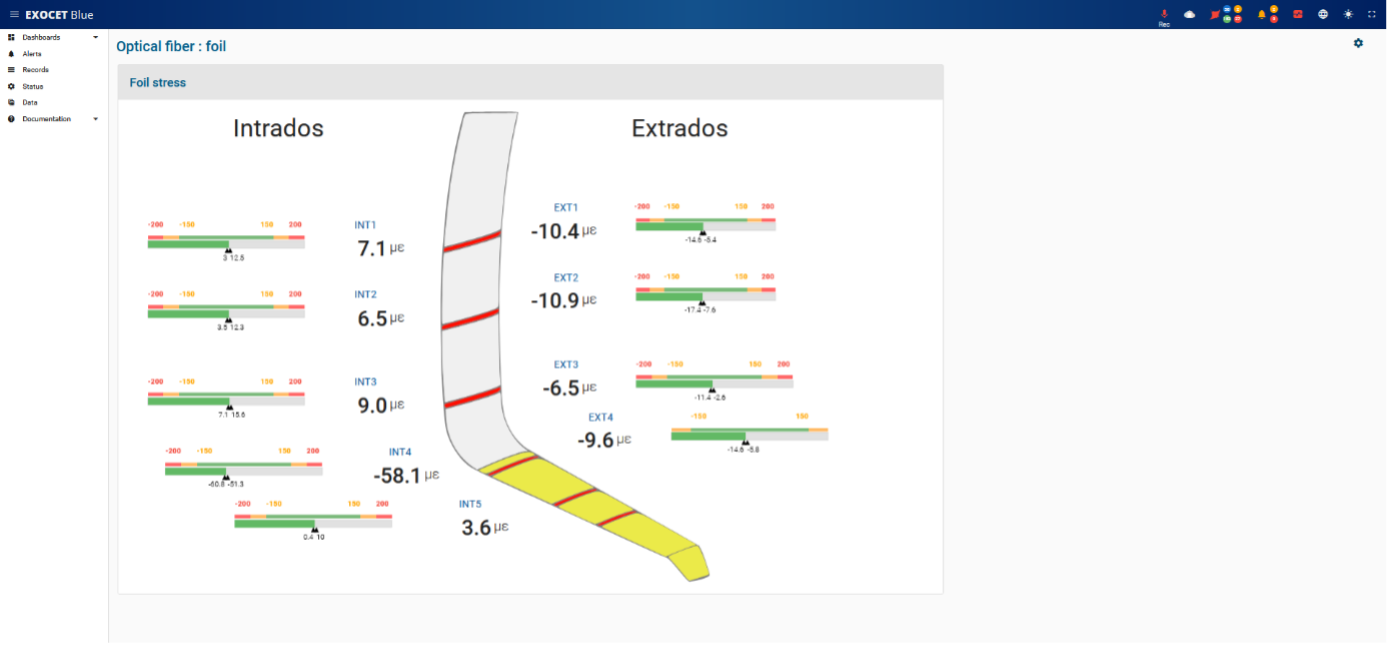

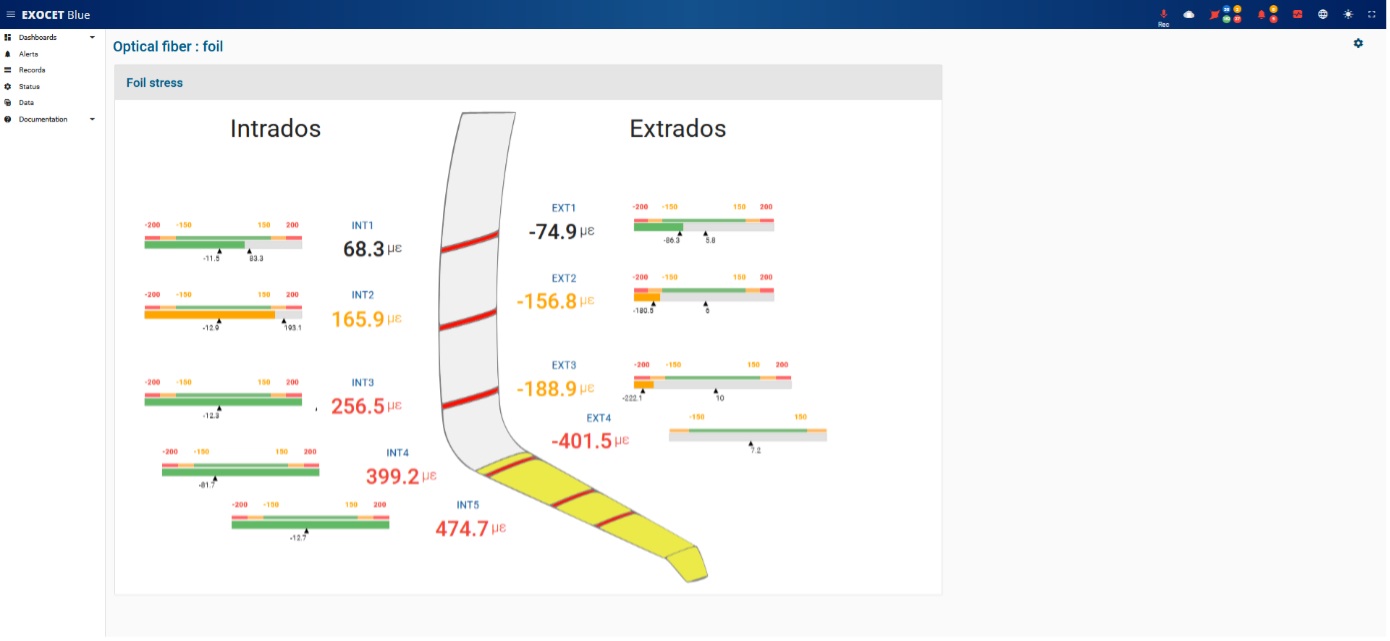

Foil Visualization – Exocet Blue Interface

Comparison of a fiber-instrumented foil in two states:

- Top: normal situation, no stress

- Bottom: foil under stress. Sensors detect significant deformations (in red) caused by hydrodynamic forces while sailing.

Thanks to Exocet Blue, teams can monitor the foil’s structural condition in real time and detect any anomaly.

Why is it innovative?

A technology designed for real-world conditions:

- Ultra-light: only a few grams, with no structural impact

- Neutral: no electromagnetic interference or signal noise

- High sensor density : monitoring extended areas

- Robust: corrosion-resistant, even in extreme marine environments

- Discreet: integrable during construction or retrofit, without altering the part

- Reliable: accurate measurements even in EM-noisy environments

Above all, it is one of the very few technologies capable of monitoring a structure’s condition in real time without altering it or interfering with its operation.

Practical applications

Anticipate failures

No need to wait for a part to break: track changes in real time, identify weak points, optimize maintenance, and prevent failures.

Improve performance

The collected data allow you to fine-tune adjustments, understand dynamic behavior (foils, masts, airplane wings, etc.), and unlocking the component’s full potential.

Design better

By integrating real-world data into your models, you can validate, or refine, your design assumptions, particularly for foils or innovative architectures.

Enhance navigation safety

Monitoring critical parts while sailing improves boat reliability… and ensures crew safety.

Verify compliance before delivery

Data collected during testing allow you to check that a part meets the specifications defined during design.

Installation, timeline, budget: what you need to know

Installing a fiber optic measurement system is simpler than it seems.

Our teams guide you in selecting the right areas to instrument, based on your objectives (safety, performance, etc.)

Two options are available:

- Embedded fiber: integrated into composite material during part fabrication. Ideal for in-depth monitoring from the design stage.

- Surface fiber: bonded or inserted on existing parts. Perfect for retrofit, with minimal modifications.

Practical aspects:

- Installation: Depending on the number of fibers, installation takes from a few hours to a few days. On average, one fiber requires about half a day.

- Cost: Costs vary depending on the extent of instrumentation but remain accessible, generally between 1.5–2.5% * of the price of a pair of foils. A small investment for high-value data that improves understanding, adjustment, and structural safety.

- Maintenance : Almost zero. Once installed, the fiber is passive, robust, and requires no intervention unless directly damaged.

Use cases on board

foils

Measure deformations along the entire foil to determine lift and facilitate adjustments (cant and rake).

Masts and rigging

Monitor mast shape in real time (bend, tilt, twist) to track asymmetric tensions, detect under-dimensioned areas, and anticipate breakage risks.

Hull

Detect impacts, track localized deformations, and anticipate structural fatigue areas.

Rudders

Analyze thrust and bending forces to secure appendage reliability.

A system integrated into your onboard environment

At Pixel sur Mer, fiber optics are combined with our onboard monitoring solution: Exocet Blue.

Exocet Blue: your onboard brain

- Acquisition of sensor data

- Synchronization with navigation data (wind, heel, speed)

- Visualization on a clear, intuitive, customized interface

- Onboard recording and transfer to shore to a cloud-based storage and visualization solution, in real time or for post-processing. This provides you with contextual insight into the structural loads experienced by your vessel.

Data replay: you can visualize past sequences, identify stress peaks, analyze and understand technical incidents, or fine-tune your settings.

A forward-looking, ever-evolving technology, supported by Pixel sur Mer’s active research

Fiber optic instrumentation is transforming how we design, sail, and operate boats.

It provides a deeper onboard understanding: capturing the invisible, predicting failures, and better grasping real structural behavior.

At Pixel sur Mer, we don’t just integrate this technology onboard, we actively contribute to its evolution.

As members of the CAFCA consortium, we take part in collaborative research projects to advance structural monitoring in demanding applications, both at sea and in the air.

Our engineers, electronics experts, and developers work daily to improve measurement and analysis tools, in direct connection with real-world conditions.

Ready to Go Further?

We recommend fiber optics if you:

- Want to better understand what your vessel experiences while sailing

- Want to anticipate failures before they occur

- Have critical components to monitor (foils, rudders, mast, etc.)

- Are developing a new part or innovative design and want to validate it under real conditions

Our team is ready to help turn your needs and ideas into concrete solutions. Do you have a project in mind, a component to monitor, or simply questions about fiber optic instrumentation?

We carefully assess your requirements and guide you step by step in building your project and integrating this cutting-edge technology – precise, robust, and intelligent – to achieve your goals.

Contact us for an initial discussion or a customized instrumentation study.