The revolution of real-time 3D sail measurement

Onboard 3D sail measurement computer. The technical core of the Exocet FlyingShape system. More accurate trim. Reliable data. Optimal use of your sails.

Until now, measuring sail shape relied on the trimmer’s eye, experience, or post-processed photo and video analysis.

A subjective, incomplete, and non-reproducible method.

Exocet FlyingShape changes everything.

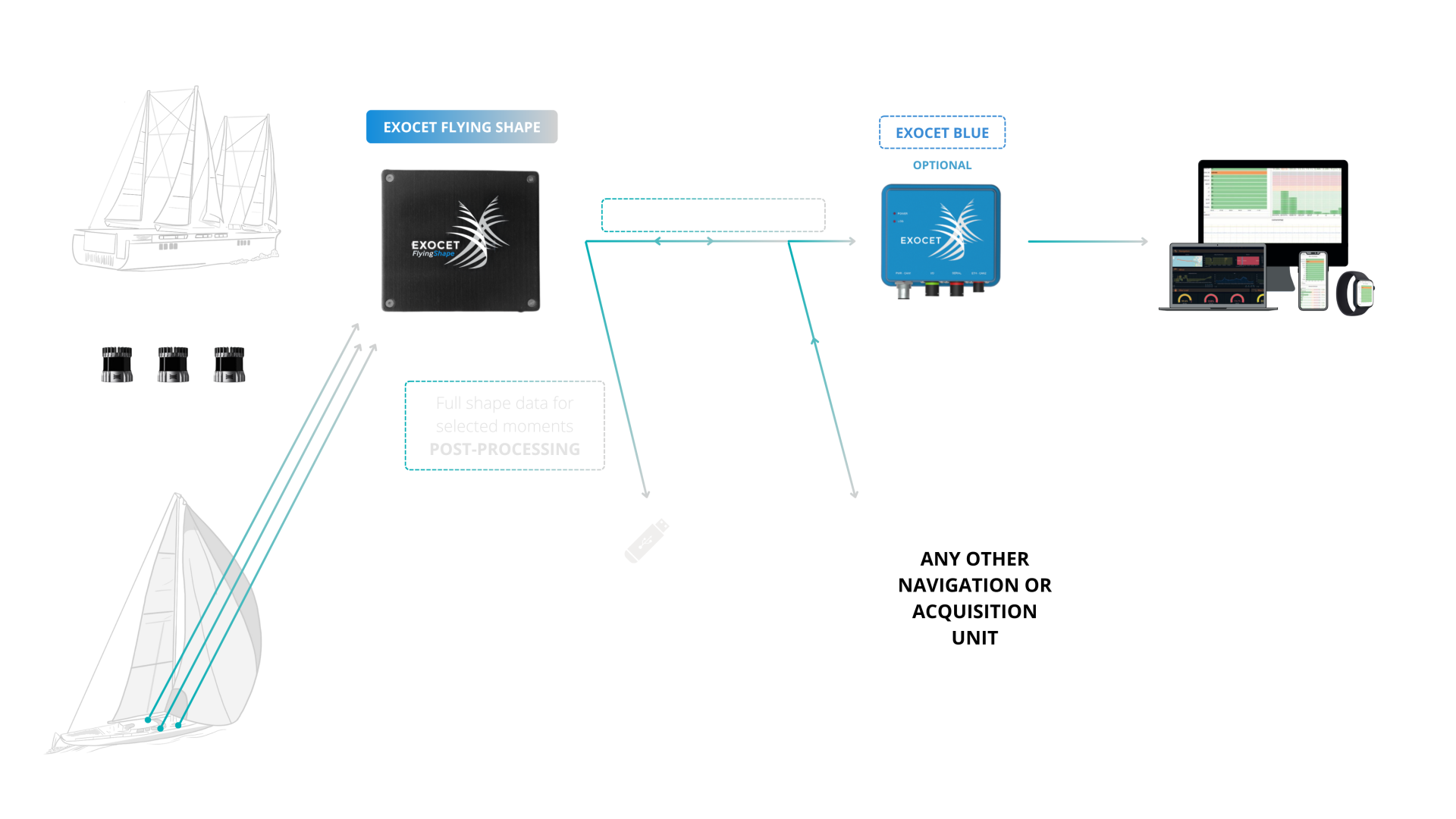

This fully integrated onboard system captures the sail’s shape in real time using multiple high-frequency LiDAR sensors.

The Exocet FlyingShape unit reconstructs the sail’s 3D profile and automatically extracts the key parameters that define its aerodynamic behavior.

With Exocet FlyingShape, sail trim becomes a precise, measurable, and repeatable process, directly accessible during navigation.

Real-time trimming

Instantly visualize the effect of every action (vang, traveller, backstay, halyard tension) and fine-tune your sails to match both the theoretical model and the boat’s actual behavior.

Reference & repeatability

Create your own sail shape polars and compare them from one navigation to another. You obtain reproducible trim settings, independent of sea state or crew.

Decision support

Adjust your trim to recover the optimal profile defined by designers, and reliably correlate the sail’s actual shape with onboard performance data.

Analysis & automation

The collected data can be used for research, simulation, and intelligent autopilot systems. Exocet FlyingShape provides a robust technological foundation for future sail trim automation.

Knowledge capitalisation

Real-world shape data under sail offers invaluable feedback to sailmakers and design offices, who can now analyze how sails are truly used at sea.

Time savings

By simplifying rig and sail plan tuning, Exocet FlyingShape delivers significant time savings during development, testing, and optimization phases.

Until now, comparing trim settings from one day to the next or validating a sail choice was only possible in post-processing, through complex, heavy systems that were difficult to install and maintain onboard.

With Exocet FlyingShape, this technology becomes:

WANT TO LEARN MORE?

Dive into the heart of the technology. Through 6 episodes, discover how FlyingShape captures the 3D shape of your sails, boosts performance, and seamlessly integrates into your boat!

From the 3D sail shape reconstructed in real time, the system continuously computes horizontal cross-sections at 25%, 50%, and 75% of the sail height, and automatically extracts:

All data are correlated in real time with navigation parameters (wind, speed, heel, rig tension, etc.) and recorded for further analysis.

Full 3D sail shapes can also be recorded at selected moments for deferred export and post-sailing analysis by race teams and sail designers.

Recommendation on sail reflectivity

For optimal performance, particularly at long range (>25 m), a sufficient reflectivity of the sail material is recommended.

The addition of reflective tapes or coatings on key areas (luff, leech) enhances detection quality and measurement accuracy.

| Exocet FlyingShape Box | |

| Weight | 650 g |

| Dimensions | 120 x 120 x 50 mm |

| Power consumption | 15–25 W |

| Operating temperature | -10 °C à +50 °C |

| Interfaces | Ethernet |

| Enclosure | Fanless aluminium - CE EN 60945 & FCC certified |

| Reconstruction accuracy | < 4 mm |

| Calculated data | Camber, draft position, twist, luff sag, leech curves, ... |

| Ouster OS0-128 LiDAR Sensors | |

| Weight | 500 g |

| Dimensions | Ø 87 mm × H 74 mm |

| Power supply | 12–24 V DC |

| Power consumption | 4.8 W (standby) / 16.8 W (active) |

| Wavelength | 865 nm |

| Field of view | 90° vertical / 360° horizontal |

| Angular resolution | 0.18° × 0.70° |

| Acquisition rate | 10 Hz |

| Precision | σ = 8 to 30 mm |

| Range | up to 75 m |

| Durability | Marine-grade sensor, resistant to vibration and salt corrosion |

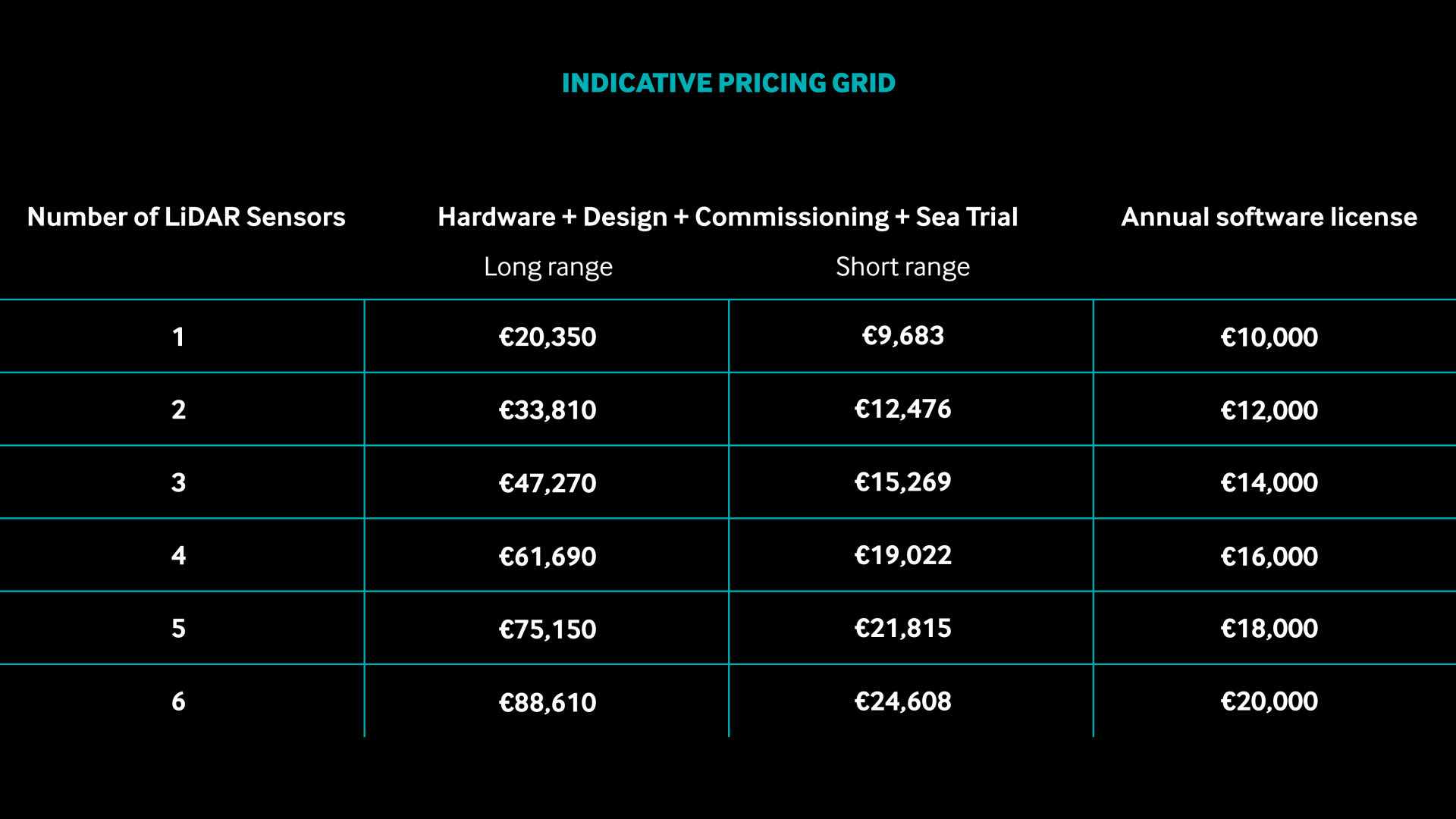

Based on your requirements, our team will define the configuration best suited to your needs. The Exocet FlyingShape solution adapts equally well to a single sail or a complete sail plan. From 1 to 6 LiDAR sensors can be integrated to provide tailored coverage and precision.

For reference: we recommend 3 LiDAR sensors to measure the mainsail and J2/J3.

Below, you will find an indicative pricing grid to give you a first look at the possible configurations.

Short-range LiDAR: TF35, Figaro, Class40, TP52, Ultim, Olympic sails

Long-range LiDAR: Maxi yachts, wind-assisted shipping projects